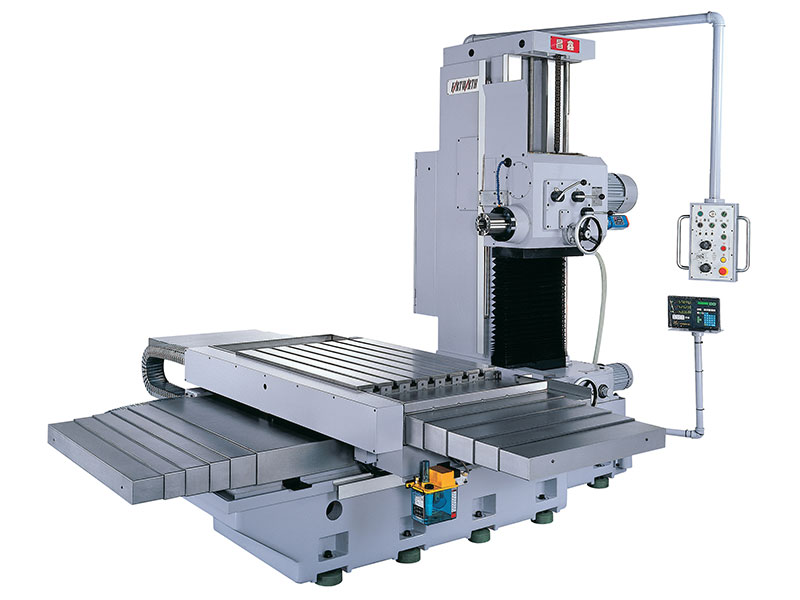

Horizontal Boring & Milling Machine

CS-HB140

Standards

- Automatic lubrication system

- Coolant system

- Index table 600x600mm 72 Divisions

- Air power draw-bar

- With Digital Read Out

- X & Z-axis with ballscrew

- Tapping function

- X.Y & Z-AXIS WITH HYDRAULIC CLAMP

- Tool box with adjustment tools

- Leveling blocks and bolts

Optional

- 1. X, Y, Z with servo motor & MPG

specification All SERIES

| ITEM | UNIT | CS-HB140 | CS-HB180 | ||||

| CAPACITY | |||||||

| Table travel (X axis) | mm | 1,400 (55-3/32 inch) | 1,800 (70-13/16 inch) | ||||

| Head travel (Y axis) | mm | 1,200 (47-3/16 inch) | 1,400 (55-3/32 inch) | ||||

|

Table travel (Z axis) |

mm | 1,100 (43-1/4 inch) | 1,250 (49-3/16 inch) | ||||

| W axis (Spindle axial) | mm | ||||||

| Spindle center to table top | mm | 0 ~ 1,200 (0 ~ 47-3/16 inch) | 0 ~ 1,400 (0 ~ 55-3/32 inch) | ||||

| Spindle end to table center | mm | 255 ~ 1,355 (10 ~ 53-1/4 inch) |

255 ~ 1,505 (10 ~ 59-1/4 inch) |

||||

| TABLE | |||||||

| Table size overall | mm | 1,100 x 800 (43-1/4 x 31-1/2 inch) |

1,500 x 800 (59 x 31-1/2 inch) |

||||

| T slot (Wide x No. x Pitch) | mm | 20 x 7 x 100 (0.78 x 7 x 3-7/8 inch) |

20 x 7 x 100 (0.78 x 7 x 3-7/8 inch) |

||||

| Table indexing (360 degree) |

degree | - | - | ||||

| Table load capacity max. | kg | 1,400 (3,090 lbs) | 2,000(4,400 lbs) | ||||

| SPINDLE HEAD | |||||||

| Spindle nose | ISO R297 No.50 | ISO R297 No.50 | |||||

| Spindle diameter | mm | - | - | ||||

| Spindle speed | 50Hz; 12 steps | rpm | 35 ~ 1,250 | 35 ~ 1,250 | |||

| 60Hz; 12 steps | rpm | 45 ~ 1,500 (opt. 30 ~ 1000) | 45 ~ 1,500 (opt. 30 ~ 1000) | ||||

| FEED / RAPID | |||||||

| X, Y, Z rapid | 50Hz | mm/min | 2,400 (94-7/16 ipm) | 2,400 (94-7/16 ipm) | 2,800 (110-1/4 ipm) | ||

| 60Hz | mm/min | 2,880 (113-3/8 ipm) | 2,880 (113-3/8 ipm) | ||||

| W rapid | mm/min | - | - | ||||

| X, Y, Z auto feed | 50Hz | mm/min | 23 ~ 730 (15/16~28-3/4 ipm) |

23 ~ 730

(15/16~28-3/4 ipm) |

20 ~ 950

(3-4 ~ 37-3/8 ipm) |

||

| 60Hz | mm/min | 28 ~ 875 (1-1/8 ~ 34-7/16 ipm) |

28 ~875

(1-1/8 ~ 34-7/16 ipm) |

||||

| W feed | mm/min | - | - | ||||

| Change of feeds | - | - | |||||

| Z axis boring feeds (12 steps) | mm/rev | 0.028 ~ 0.875 | 0.028 ~ 0.875 | ||||

| MOTORS | |||||||

| Spindle motor | kW | AC 7.5 (10HP)-4P | AC 7.5 (10HP)-4P | ||||

| Feed motor | kW | AC 1.5 (2HP)-4P | AC 1.5 (2HP)-4P | AC 2.9 (3.8HP) servo motor |

|||

| Feed motor for X, Y, Z axis (Servo) | kW | - | - | ||||

| Feed motor for W axis (Servo) | kW | - | - | ||||

| Lube pump for headstock | kW | AC0.18-4P | AC0.18-4P | ||||

| Lube pump for slideways | W | AC3.5 | AC3.5 | ||||

| Coolant pump | kW | AC 0.12(1/6HP)-2P | AC 0.12(1/6HP)-2P | ||||

| Hydraulic pump for axis clamp | kW | AC 1.5(2HP)-4P | AC 1.5(2HP)-4P | ||||

| MACHINE SIZE | |||||||

| Machine height | mm | 2,800(110 inch) | 3,070(120-13/16 inch) | ||||

| Floor space (Longitudinal x cross) |

mm | 3,606 x 3,600 (142 x 141-3/4 inch) |

4,420 x 3,750 (174 x 147-5/8 inch) |

||||

| Net weight (Approx.) | kg | 8,400 (18,520 lbs) | 11,500 (25,350 lbs) | ||||

| Standard color | - | Gray | Gray | ||||

*Design and specifications are subject to change without prior notice.

Copyright © Chung Sing Machinery Co., LTD.

Design byTaiwan Products, B2BManufactures, B2BChinaSources