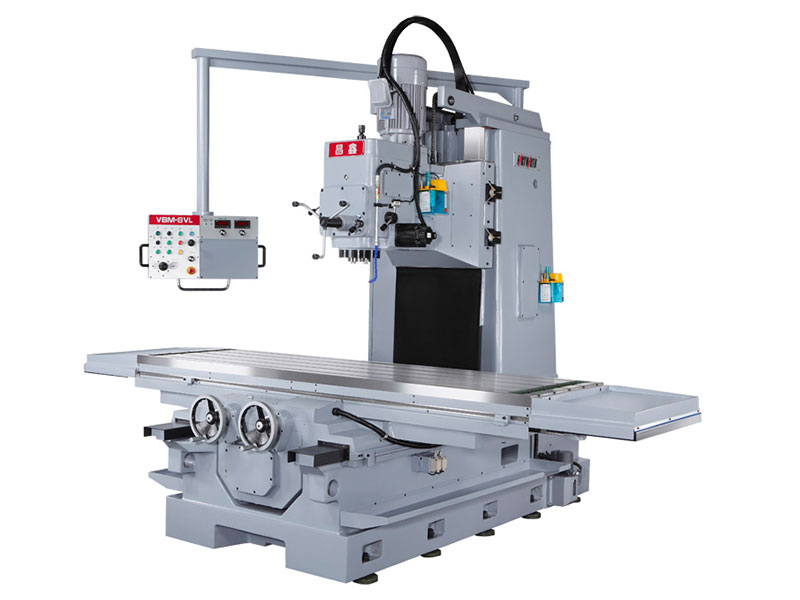

Bed Type Vertical Boring & Milling Machine

CS-VBM-8VL

Standards

- Cutting fluid device 1 unit

- Tools and box 1 set

- Leveling blocks 10 pcs

- Leveling bolts & nuts 10 sets

- Draw bar 1 pc

Optional

- Digital read out

- Air power draw bar

- Working lamp

specification ALL SERIES

| ITEM | UNIT | CS-VBM-3V-A | CS-VBM-5VL | CS-VBM-5VL-L | CS-VBM-8VL | CS-VBM-8VL-L | |||||

| CAPACITY | |||||||||||

| Table travel (Longitudinal) | mm | 1,000 (39-3/8 inch) | 1,500 (59 inch) | 2,000 (78-3/4 inch) | 2,000 (78-3/4 inch) | 2,500 (98-7/16 inch) | |||||

| Table travel (Cross) | mm | 380 (14-15/16 inch) | 600 (23-5/8 inch) | 600 (23-5/8 inch) | 800 (31-1/2 inch) | 800 (31-1/2 inch) | |||||

| Spindle head travel (Vertical) | mm | 500 (19-11/16 inch) | 700 (27-9/16 inch) | 700 (27-9/16 inch) | 700 (27-9/16 inch) | 700 (27-9/16 inch) | |||||

| Spindle nose to table top | mm | 100 ~ 600 (3-15/16 ~ 23-5/8 inch) |

100 ~ 800 (3-15/16 ~ 31-1/2 inch) |

100 ~ 800 (3-15/16 ~ 31-1/2 inch) |

70 ~ 770 (2-3/4 ~ 30-1/4 inch) |

70 ~ 770 (2-3/4 ~ 30-1/4 inch) |

|||||

| Spindle center to column | mm | 380 (14-15/16 inch) | 550 (21-5/8 inch) | 550 (21-5/8 inch) | 800 (31-1/2 inch) | 800 (31-1/2 inch) | |||||

| TABLE | |||||||||||

| Table working area | mm | 1,700 x 380 (67 x 14-15/16 inch) |

2,200 x 500 (86-5/8 x 19-11/16 inch) |

2,700 x 500 (106-1/4 x 19-11/16 inch) |

2,700 x 750 (106-1/4 x 29-1/2 inch) |

3,200 x 750 (126 x 29-1/2 inch) |

|||||

| T slot (Wide x No. x Pitch) | mm | 18 x 5 x 70 (0.709 x 5 x 2-3/4 inch) |

18 x 5 x 90 (0.709 x 5 x 3-9/16 inch) |

18 x 5 x 90 (0.709 x 5 x 3-9/16 inch) |

18 x 5 x 150 (0.709 x 5 x 5-7/8 inch) |

18 x 5 x 150 (0.709 x 5 x 5-7/8 inch) |

|||||

| Table top to floor | mm | 810 (31-7/8 inch) | 870 (34-1/4 inch) | 870 (34-1/4 inch) | 900 (35-7/16 inch) | 900 (35-7/16 inch) | |||||

| SPINDLE HEAD | |||||||||||

| Spindle nose | ISO R297 No.50 | ISO R297 No.50 | ISO R297 No.50 | ISO R297 No.50 | ISO R297 No.50 | ||||||

| Spindle speed | rpm | 50Hz | 35 ~ 1,250 | 50Hz | 35~1,250 | 50Hz | 35~1,250 | Low | 45~250 | Low | 45~250 |

| 60Hz | 45 ~ 1,500 | 60Hz | 45~1,500 | 60Hz | 45~1,500 | High | 250~1,500 / Infinitely variable |

High | 250~1,500 / Infinitely variable |

||

| No. of spindle speed | steps | 12 | 12 | 12 | 2 | 2 | |||||

| Z axis feeds (Vertical spindle) | mm/min | - | - | - | 3 ~ 300 (0.12 ~ 11.81 ipm) |

3 ~ 300 (0.12 ~ 11.81 ipm) |

|||||

| Feeds (Vertical spindle) | mm/rev. | 0.05 ~ 0.2 (0.0025 ~ 0.01 ipr) |

0.05 ~ 0.2 (0.0025 ~ 0.01 ipr) |

0.05 ~ 0.2 (0.0025 ~ 0.01 ipr) |

- | - | |||||

| FEED / RAPID | |||||||||||

| Rapid traverse (Longitudinal & cross) |

mm/min | 2,800 (110 ipm) | 3,300 (129-7/8 ipm) | 3,300 (129-7/8 ipm) | 3,100 (122 ipm) | 3,100 (122 ipm) | |||||

| Feed rates (Longitudinal & cross) |

mm/min | 28 ~ 1,000 (1-1/8 ~39-3/8 ipm) |

28 ~ 1,000 ( 1-1/8 ~ 39-3/8 ipm) |

28 ~ 1,000 (1-1/8 ~ 39-3/8 ipm) |

28 ~ 1,000 (1-1/8 ~ 39-3/8 ipm) |

28 ~ 1,000 (1-1/8 ~ 39-3/8 ipm) |

|||||

| Change of feeds | steps | Infinitely variable | Infinitely variable | Infinitely variable | Infinitely variable | Infinitely variable | |||||

| MOTORS | |||||||||||

| Vertical spindle | kW | AC 5.5 (7.5HP)-4P | AC 11 (15HP)-4P | AC 11 (15HP)-4P | AC 11 (15HP)-4P | AC 11 (15HP)-4P | |||||

| Feed of X, Y axis | kW | AC 1.3 (1.74HP) Servo motor |

AC 1.5 (2HP)-6P (Inverter motor) |

AC 1.5 (2HP)-6P (Inverter motor) |

AC 3.5 (4.7HP) Servo motor |

AC 3.5 (4.7HP) Servo motor |

|||||

| Feed of Z axis | kW | - | - | - | AC 1.3 (1.75HP) Servo motor |

AC 1.3 (1.75HP) Servo motor |

|||||

| Lubrication | W | AC 3.5 | AC 3.5 | AC 3.5 | AC 3.5 | AC 3.5 | |||||

| Cutting fluid | kW | AC 0.12 (1/6HP)-2P | AC 0.12 (1/6HP)-2P | AC 0.12 (1/6HP)-2P | AC 0.12 (1/6HP)-2P | AC 0.12 (1/6HP)-2P | |||||

| MACHINE SIZE | |||||||||||

| Machine height | mm | 2,453 (96-9/16 inch) | 2,870 (113 inch) | 2,870 (113 inch) | 2,923 (115 inch) | 2,923 (115 inch) | |||||

| Floor space (Longitudinal x cross) |

mm | 3,200 x 1,960 (126 x78 inch) |

4,440 x 2,550 (174-7/8 x 100-3/8 inch) |

5,690 x 2,550 (224 x 100-3/8 inch) |

5,694 x 3,075 (224-3/16 x 121 inch) |

6,940 x 3,075 (273-1/4 x 121 inch) |

|||||

| Net weight (Approx.) | kg | 4,000 (8,800 lbs) | 7,000 (15,400 lbs) | 7,700 (16,940 lbs) | 11,800 (26,000 lbs) | 13,200 (29,040 lbs) | |||||

| Standard color | Gray | Gray | Gray | Gray | Gray | ||||||

*Design and specifications are subject to change without prior notice.

Copyright © Chung Sing Machinery Co., LTD.

Design byTaiwan Products, B2BManufactures, B2BChinaSources